BOP

MU BOP

The MU BOP is the most widely use ram BOP in the world. Its simple, compact design makes it well suited for operation offshore and onshore.The one piece type MU ram provides a pressure energized seal and maximum contact area to the drill pipe. MU ram BOP is designed to provide a fast and reliable closure around pipe or casing in the well bore. The sealing is energized by the pressure and maintained even with loss of closing pressure.ALL MU BOPs are manufactured to comply with specificantion MR-01-75 for H2S service.

MSP/DRILEX can supply server service MU BOP to meet our customer’s specific requirements including qualified ram packers,top seals and bonnet seal kits for extreme servicer conditions , high or low temperature , and harsh chemical environment. MSP/DRILEX offers a wide selection of rams to meet all applications.

Special Features

• Manufactured per API 16A

• Utilizes type MU rams

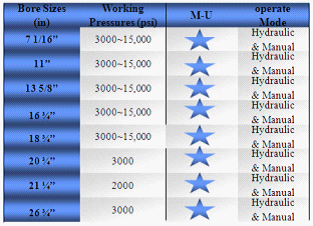

• Available in bore size 7-1/16” thru 26-3/4” and in working pressure from 2000psi thru 15000psi

• Manufactured per NACE MR-01-75.All the parts of MU BOP are suitable for H2S service

• Field-replacement bonnet cylinders, seals and pistons

• Easy installation and maintenance, little replacement parts

• Rams are self-feeding and incorporate a larger reservoir of packer rubber to ensure a long-lasting seal under all conditions. It cannot be dislodged by fluid flow

• Choice of manual and hydraulic locking devices

• Quick ram change-out designed

• Bonnets are opened and closed by hydraulic pressure

• Uniquely secondary ram shaft seals designed. Ram shaft packing protects operating mechanism from wellbore pressure and contamination by wellbore fluid

• All major components parts are forged for uniform strength, impact resistance and freedom form defects

• Top&bottom connections and side outlets per cunstomer requirements

• Available with pipe rams, bland rams, variable rams and shearing rams